Here’s an uplifting yarn for you, one involving a few sleepless nights, huge amounts of money, a giant cardboard box from Japan, an old farm building and an awful lot of hard work.

Ultimately, it’s a tale about taking control of your own destiny during the most challenging of times and fulfilling a desire to craft a better, more certain future.

Orkney textile designer Hilary Grant and her partner Robbie Harvey had been happily running their successful and well-established knitwear business on the shores of Orphir’s Houton Bay when the COVID-19 pandemic hit in 2020.

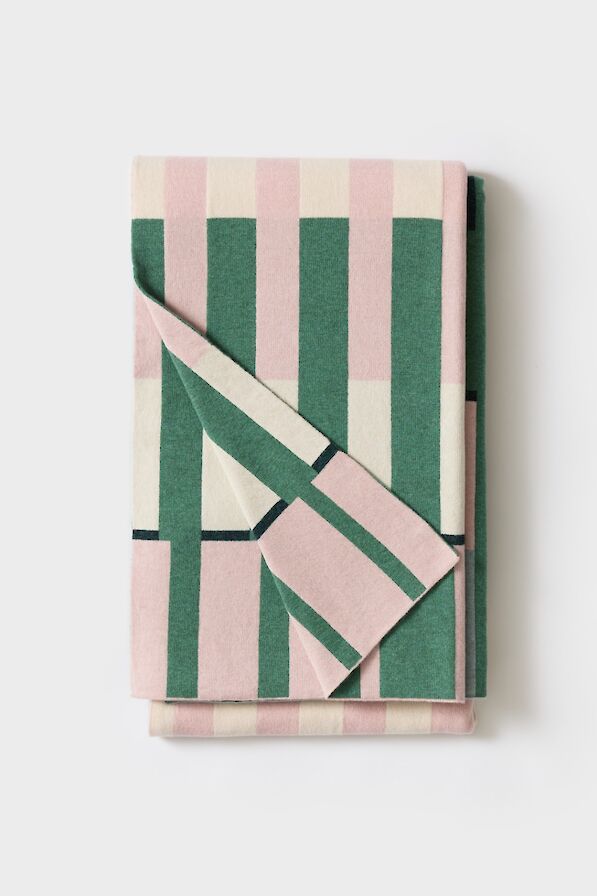

Hilary, who graduated in textile design from Dundee’s Duncan of Jordanstone College of Art and Design in 2007, set up the business in 2011. Demand for her collections of lambswool hats, blankets, scarves and mittens grew rapidly, with the Hilary Grant range going on to sell in prestigious independent boutiques and stores around the world.

When she was starting out, Hilary made everything herself. But as national and international demand for her products increased, she moved manufacturing to specialist textile factories in the Scottish Borders. The ranges were all still designed at Hilary and Robbie’s Houton studio, with the raw material – premium quality lambswool yarn – sourced from a mill in Kinross.

As a business model it was all working smoothly, until COVID-19 came along.

Suddenly, there were gaps appearing in Hilary and Robbie’s vital supply chain – small textile factories having to close, and delays in samples and orders reaching Orkney.

“With all these things happening with COVID-19 and the delays it was causing, we realised we didn’t have that much control over our own supply chain,” recalls Hilary. “It was all pretty fragile, and it would just take a couple of the mill staff down south being off, or a small factory in the Borders closing for a couple of weeks, for production to become quite unpredictable.”

“The systems had broken down,” adds Robbie. “The conclusion we came to off the back of the pandemic was that the only control we had was the control we could take for ourselves. If we were going to make it ourselves, then we felt we were going to get things done properly.”

It sounds like a simple and obvious solution. But producing premium quality textile goods in Orkney, in the quantities demanded by retail and trade customers, was going to need some large-scale investment and some specialist equipment, too.

An added hurdle was the fact that Hilary and Robbie’s Houton studio, which is attached to their home, simply wasn’t big enough to accommodate on site production, so they’d also need to find a lot more space.

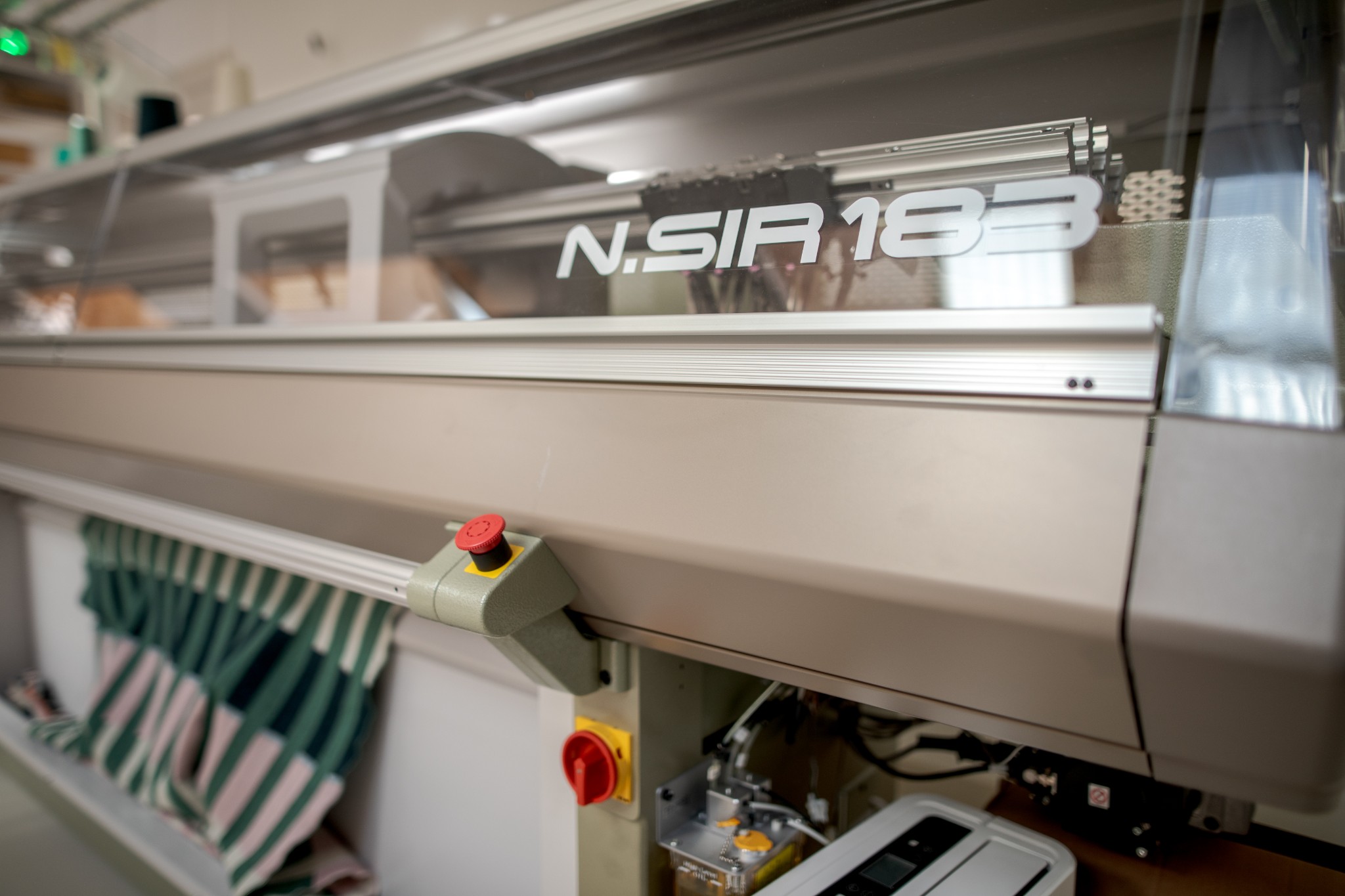

Undaunted, the couple set their ambitious plan in action. They managed to secure £75,000 of post-pandemic recovery funding from the Islands Green Recovery Programme to help towards the costs of buying a huge industrial Shima Seiki knitting machine from Japan.

“It’s the same kind of machinery that’s used to make world-class knitwear for really high-end luxury brands, and has lots of technology that allows us to develop our collection and reduce waste in the knitting process,” explains Hilary. “The machines are made to order, and you must specify the gauge of needles you want to use. It also comes with specialist software so we can design and sample.”

With the machine measuring 3.5 metres long and weighing in at 1.5 tonnes, it wasn’t going to fit into Hilary and Robbie’s Houton studio, but family came to the rescue.

“My parents offered us a shed at their farm in Birsay,” says Robbie. “My dad had retired from farming and the buildings were sat doing nothing, so it was ideal.”

Work began on transforming the former implement shed into a textile factory a couple of years ago, with Hilary and Robbie doing the bulk of the work themselves with some help from Robbie’s father. They continued to run their business from Houton in the meantime.

The knitting machine, transported by sea from Japan, finally arrived in November of last year - before the factory building was finished.

“It came on a metal pallet but was inside a huge cardboard box,” laughs Robbie. “It was a bit of a feat by hauliers Northwards to get it into the building here, but after some head scratching they managed. We then had to work around it as we painted and finished the factory.”

Production got underway in August, after Hilary and Robbie had learned how to use the knitting machine and its sophisticated software, invested in more expensive specialist equipment - in the form of a linker from Italy - and bought in a good stock of premium lambswool yarn from Kinross.

Understandably, it’s been a blur for the pair, but they’re already reaping the benefits of all their time, money and hard work.

“We had a few sleepless nights along the way!” laughs Hilary. “We didn’t really know this year if we were going to be able to make an entire collection ourselves, as some of the machinery had only arrived in August, but we’ve managed to do it.

“We’ve remastered a lot of our existing designs and added in lots of details with the finishing and construction. It’s the level of detail that’s quite hard to justify if you’re getting a factory south to do it as there’s a lot of going back and forwards, but we’ve been able to look at everything from scratch.”

Robbie agrees that it’s been transformative.

“It’s streamlined the design process and we’ve got more control at our fingertips now,” he explains. “Before, we couldn’t sample colours in real-time. We can knit swatches now and do much more with subtle colour differences. There are so many more possibilities for new designs and developing new products.”

Although they’re now fully up and running with Orkney production, Hilary and Robbie are taking a typically measured approach to the development of the business. They’re currently focusing on fulfilling orders from their online shop ahead of Christmas and are working with a select handful of stockists, including The Pier Arts Centre in Stromness and The Longship in Kirkwall.

“Next year, we’re hoping to offer more wholesale,” says Robbie. “The wholesale trade for companies like us definitely suffered during the covid pandemic, but we’re just now at the point where we can build it back up and there is the demand again too. We know we can offer reliable lead times to wholesalers again because we’re doing it ourselves and it’s a lot more predictable.”

Regardless of how much demand for the Hilary Grant range develops over the coming years, sustainability will remain a cornerstone for the business. The yarn they use is sourced from farms with very high animal welfare standards and progressive land management practices, and dyes are environmentally friendly.

Hilary also reveals that they hope to open their doors and offer some small-scale production to other Orkney knitwear companies.

“It's one of the things we’ve wanted to do from the outset,” she says. “To access the kind of machinery we now have, you’d often need to place very high order quantities, far in advance, so you can work with the mills down south. It’s been a huge undertaking in time, expense and energy to set up, but we’re hoping to be able to offer production to other Orkney knitwear companies in the future so they can benefit too.”

Browse the latest Hilary Grant range on the official website. You can also follow Hilary on Instagram.